Pass Box

Pass box is one of the cleanroom systems, which is used to transfer materials from one side to other side through controlled environment in order to avoid airborne cross contamination. As the name states itself, the primary and only work of a pass box is to pass material from one side to other without raising contamination concern and if any particulate matter presents on the material surface, it swipes away during the operation. Interlocking door mechanism is the prime feature of a pass box, when door at one side is open the door at other side remains closed. It is popular with other names such as cleanroom pass through, clean transfer window and transfer hatch; in addition, it is widely used in Microbiology Laboratories in Food, Pharmaceutical, Chemical Industries and Hospital A pass box is designed in two different types; Static and Dynamic, it is the user specific requirement which decides the right design configuration

Static pass box on the other hand is fitted only between two clean room areas and has no air supply or extract. It is also known as passive pass box and equipped with UV Light

A dynamic pass box is fitted between classified and non-classified areas. Material is passed through vertically HEPA filtered air.

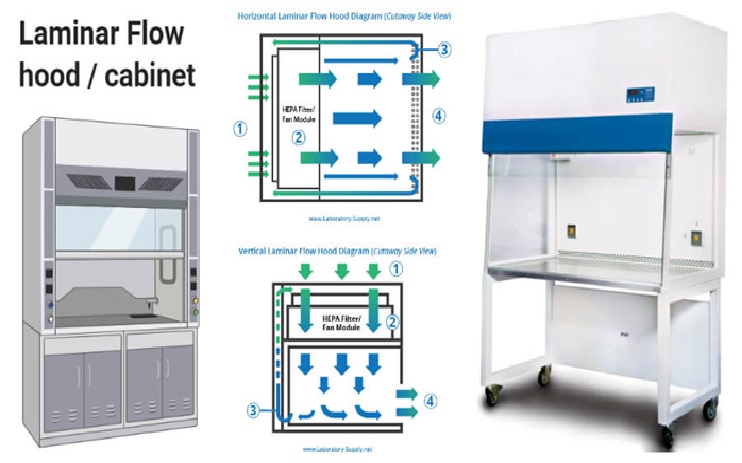

LAMINAR AIR FLOW

A laminar air flow is a closed cabinet fitted with HEPA filtered air flow system. Here, laminar means unidirectional constant flow of air with almost no or minimal turbulence. The air flow velocity remains between 0.3 m/s to 0.5 m/s. The purpose of using such workstations in laboratory is to create particle and bacteria free working environment to carry out specialized work. As these unit’s discharge air towards user, they provide no personal protection but product protection from room contaminants .LAF is short form of laminar air flow.

TYPES OF LAMINAR AIR FLOW

There are two different types of laminar air flow cabinets are constructed; horizontal and vertical. The difference between vertical and horizontal laminar flow hoods is direction of air flow and placement of HEPA filter. These cabinets are made with either horizontal or vertical air flow systems and have two stages filtration. It is the type of application which decides which is most suitable to use.

VERTICAL VS HORIZONTAL LAMINAR FLOW

| Vertical Laminar Air Flow | Horizontal Laminar Air Flow |

| It is the most used type of laminar air flow. In vertical flow cabinet, room air is entered in Working area through HEPA filter fitted on top of the cabinet. Thus, air flows downward (Vertically) towards work surface and leaves the cabinet sweeping out particles and bacteria. | In horizontal air flow cabinet, room air is entered in working area through HEPA filter fitted on the back side of the cabinet. Filtered air flows horizontally towards the user creating sterile working environment. |

In horizontal air flow cabinet, room air is entered in working area through HEPA filter fitted on the back side of the cabinet. Filtered air flows horizontally towards the user creating sterile working environment.

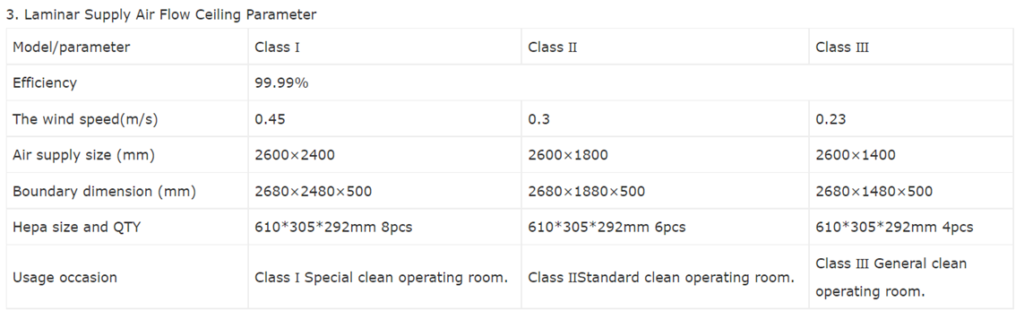

Ceiling Suspended Laminar Air Flow Unit

The air flow ceiling is widely used at operation room and laminar flow room as final filtration system. It has the effect of a high efficiency filtration, current and airflow compensation function. A3G series clean air ceiling is the crystallization of the experience and practice of the operating room supplying air. . The use of this equipment can be a reasonable distribution of clean room airflow, and to effectively guarantee the indoor cleanliness. The air ceiling is widely used at operation room and laminar flow room as final filtration system. It has the effect of a high efficiency filtration, current and airflow compensation function

Laminar Supply Air Flow Ceiling Advantages

In order to improve medical care quality, and to reduce postoperative infection, more and more hospitals adopt modern medical purification technology in the Pre-Operation Rooms, Operating Theatres, Delivery Rooms, ICU, Recovery Rooms, etc. It is crucial for clean rooms and operating theatres to be kept dust-free and for moisture and temperature to be regulated. For this reason, it is necessary for laminar flow ceiling to be mapped properly and to be controlled.

Sampling/Dispensing Booth

Assembled dispensing booth, also called sampling or weighing booth, down flow booth or powder containment booth, is dedicated purification equipment for sampling, weighing and analysis. It can contain powders and particles within work area and prevent operator from inhaling them

- Negative pressure design contains powder and particles inside booth, not overflowing booth

- Stainless steel construction make booth clean and hygienic

- Assembly design makes it possible to enter completed clean room

- Complete with user’s manual, assembly drawing, quality certificate, test report, etc.

- One set of pre-filter and medium efficiency filters as spare parts

Technical specification

- Cabinet fabricated in SS 304/316

- Air flow direction: Down

- Design according to GMP-guideline easy to clean and to disinfect.

- Specially design centrifugal or back-ward curved type air blower

- Magnehelic differential pressure gauge

- Soft touch LED controller for blower/light/pressure display

- Sensitive oxygen sensor with safety hooter

- Mini-plate HEPA filters H-14, 99.997% down to 0.3µ.

- Pre-filter non-woven, HDPE mesh EU-04 95% efficiency 5 µ

- Florescent light

- PAO port/atmospheric nozzles

- Sound level minimum 65db on scale

- Power supply single phase 220v 50 HZ

Air Showers

Air Showers are self-contained chambers installed strategically at entrances to cleanrooms and other controlled environments. They minimize particulate matter entering or exiting the clean space to mitigate the risk for cross-contamination.

How an Air Shower Works

- Completely self-contained, pre-wired, fully equipped Air Shower/Tunnel systems help solve decontamination problems

- Modular design lets you order a system to suit your cleanroom

- HEPA filter/blower modules (rated 99.97% efficient @ 0.3-micron particles) wash personnel with Class 100 air to dislodge and remove particles

- Solid-state microprocessor panel provides programmable control over access door operation

- Interlocking doors minimize contamination, release automatically in the event of power failure

- Fluorescent lighting is housed in the ceiling for minimal turbulence

- Available in white epoxy-finished CR steel, stainless steel, or plastic laminate to meet various cleanroom requirements

- Variety of sizes and door configurations

- Economical to operate, easy to maintain

- System options include HEPA-filtered ceiling, ionized grid, and safety glazing

- These Air Showers and Tunnels offer an effective way to remove surface-deposited particles from personnel—before they get to the cleanroom.

De-Dusting Tunnel With Brushing System

The SS De-Dusting Tunnel with Brushing System is a high-performance solution designed to effectively remove dust, fine particles, and surface contaminants from various products during production. Constructed entirely from stainless steel (SS 304/316), this hygienic and corrosion-resistant tunnel is ideal for food, pharmaceutical, electronics, printing, packaging, and industrial applications.

🔧 Key Features:

- Stainless Steel Construction:

- Durable, corrosion-resistant SS 304/316 build for long service life and compliance with GMP and hygiene standards.

- Integrated Brushing System:

- High-quality rotating and/or oscillating brushes with soft or anti-static bristles.

- Adjustable brush pressure to accommodate different product types and sizes.

- Efficient Dust Removal:

- Powerful dust extraction system (HEPA or cartridge filters optional).

- Optional ionized air blowers or air knives to eliminate static-clinging dust.

- Enclosed Tunnel Design:

- Fully or semi-enclosed structure prevents dust dispersion into the environment.

- Transparent inspection windows available upon request.

- Adjustable Conveyor System:

- Variable speed conveyor to match production line requirements.

- Food-grade or anti-static belts available based on application.

- User-Friendly Control Panel:

- Touchscreen or push-button interface.

- Controls for brush speed, conveyor speed, air blowers, and extraction system.

- Low Maintenance Design:

- Quick-release brushes and easy-access panels for cleaning and maintenance.